Top Wear Resistant Steels Manufacturers in China: Quality & Reliability

As a buyer in search of reliable wear resistant steels manufacturers, I understand the importance of high-quality materials for my projects. Sourcing from China, I find a diverse range of manufacturers specializing in wear resistant steels that deliver durability and performance. These steels are engineered to withstand extreme abrasion, making them ideal for industries like mining, construction, and heavy machinery. When evaluating suppliers, I prioritize their expertise and production capabilities, ensuring they offer competitive prices without compromising quality. Many Chinese manufacturers also provide customization options, allowing me to meet specific project requirements. Their commitment to innovation and customer service often stands out, giving me peace of mind throughout our partnership. Choosing the right wear resistant steels partner can impact my operations significantly. By collaborating with top manufacturers from China, I can ensure that my projects not only meet industry standards but also excel in durability.

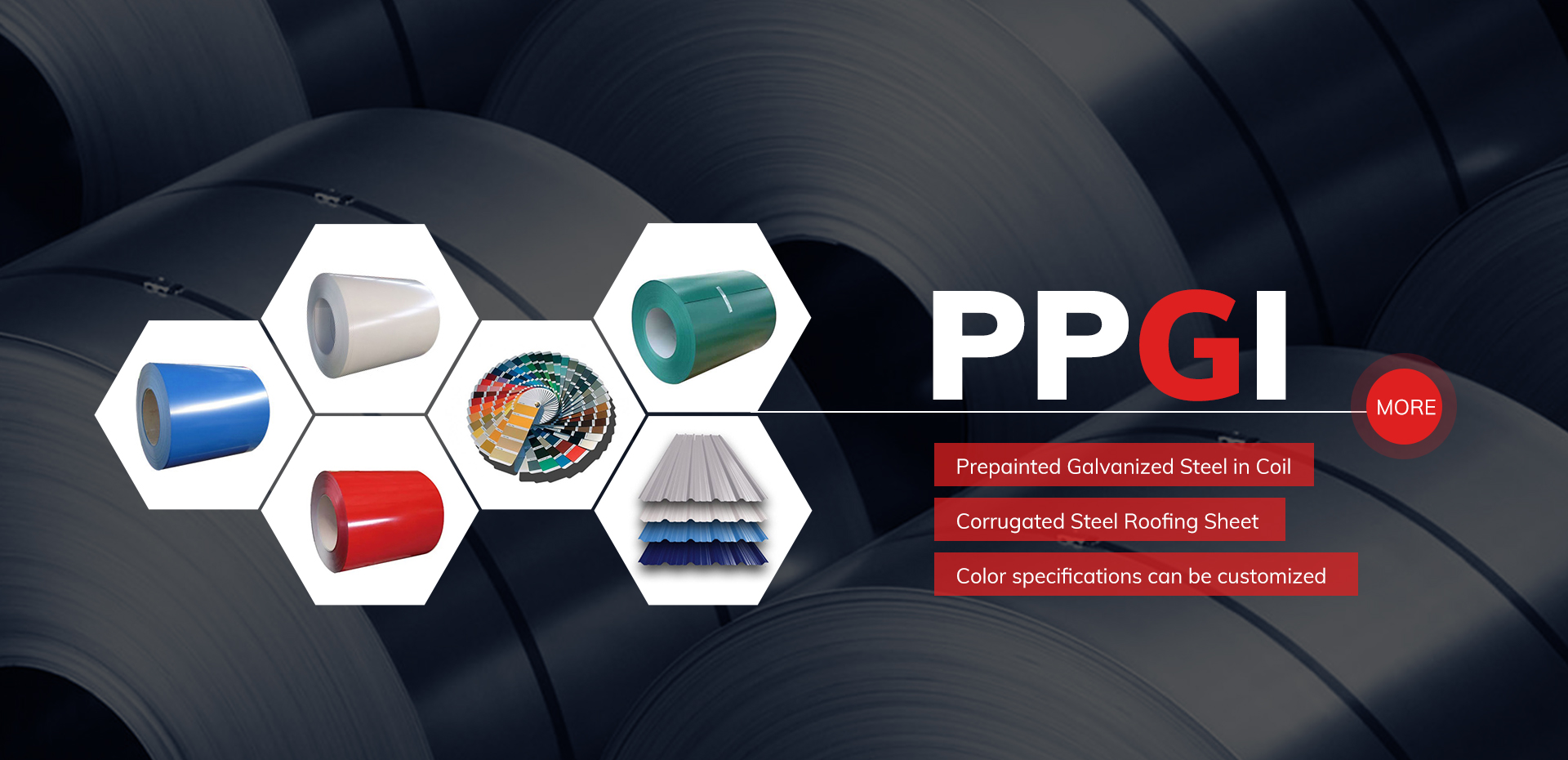

Wear Resistant Steels Manufacturers Leads the Global Market Custom Solutions,

In the ever-evolving landscape of industrial manufacturing, wear-resistant steels have emerged as a critical component for companies seeking durability and efficiency in their operations. With a focus on custom solutions, leading manufacturers are now positioned to cater to the diverse needs of global buyers. These high-performance materials not only enhance the longevity of machinery but also contribute to reduced downtime and maintenance costs, making them an invaluable asset in today’s competitive market. The unique properties of wear-resistant steels, including their hardness, toughness, and ability to withstand extreme wear and tear, set them apart from conventional materials. Industries such as mining, construction, and recycling increasingly rely on these advanced steels to optimize performance and productivity. Custom solutions allow for tailored specifications that meet the specific demands of various applications, ensuring clients receive the perfect fit for their operational requirements. By partnering with experienced manufacturers, procurement professionals can unlock the potential of their operations, driving innovation and efficiency. As the global market for wear-resistant steels continues to expand, now is the perfect time for companies to explore the benefits of these materials. Whether you are looking to enhance your existing processes or invest in new technologies, collaborating with top-tier manufacturers can provide you with the expertise and products needed to stay ahead. Embrace the opportunity to elevate your manufacturing capabilities and secure a competitive edge in the global market.

Wear Resistant Steels Manufacturers Leads the Global Market Custom Solutions

| Region | Market Share (%) | Growth Rate (%) | Key Applications | Major Industries |

|---|---|---|---|---|

| North America | 30 | 5.0 | Construction, Mining | Mining, Construction |

| Europe | 25 | 4.5 | Automotive, Oil & Gas | Automotive, Energy |

| Asia-Pacific | 40 | 6.0 | Shipbuilding, Heavy Machinery | Manufacturing, Shipbuilding |

| Latin America | 3 | 3.0 | Construction, Agriculture | Agriculture, Construction |

| Middle East & Africa | 2 | 2.5 | Oil & Gas, Construction | Energy, Construction |

Related Products