Top Special Steel Manufacturer in China for Quality Solutions

When it comes to sourcing special steel, I understand how crucial it is for you to find a reliable manufacturer in China. Our special steel products are engineered to meet the highest industry standards, ensuring that they perform exceptionally in various applications. With years of experience, we pride ourselves on our commitment to quality and customer satisfaction. Our expert team is dedicated to helping you identify the perfect solution for your needs, whether it’s for construction, automotive, or any other industry. The durability and strength of our special steel make it an ideal choice for those who prioritize reliability and performance. You'll find that our competitive pricing combined with prompt delivery sets us apart from others in the market. Let us be your trusted partner in your special steel procurement journey. Together, we can achieve remarkable results that will elevate your projects to the next level.

Special Steel in 2025 Ahead of the Curve

As we look ahead to 2025, the landscape of special steel production and procurement is rapidly evolving. Global demand for specialized steel products has surged, driven by advancements in technology and an increasing emphasis on durable, high-performance materials across various industries, including automotive, aerospace, and construction. This situation opens exciting opportunities for procurement professionals seeking reliable suppliers who can offer not only quality but also innovation in special steel solutions. To stay ahead of the curve, it’s crucial for procurement managers to be aware of the latest trends and advancements in special steel manufacturing. Innovations such as advanced alloys, eco-friendly production techniques, and tailored solutions to meet specific operational needs are now at the forefront of the industry. Collaborating with manufacturers who prioritize research and development can provide significant advantages, allowing companies to remain competitive in a fast-paced market. In this dynamic environment, establishing strong partnerships with suppliers who understand the complexities of global logistics and can deliver consistent quality is vital. As businesses navigate supply chain challenges, selecting a partner dedicated to excellence and sustainability will be key to future success. Embracing these shifts early will not only ensure access to cutting-edge materials but also position companies strategically for sustained growth in the years to come.

Special Steel in 2025 Ahead of the Curve

| Material Type | Strength (MPa) | Hardness (HB) | Usage | Future Trends |

|---|---|---|---|---|

| Alloy Steel | 700 | 250 | Automotive | Increased Demand |

| Stainless Steel | 600 | 200 | Construction | Sustainability Focus |

| Carbon Steel | 550 | 180 | Machinery | Advanced Processing |

| Tool Steel | 900 | 350 | Manufacturing | Innovation in Alloys |

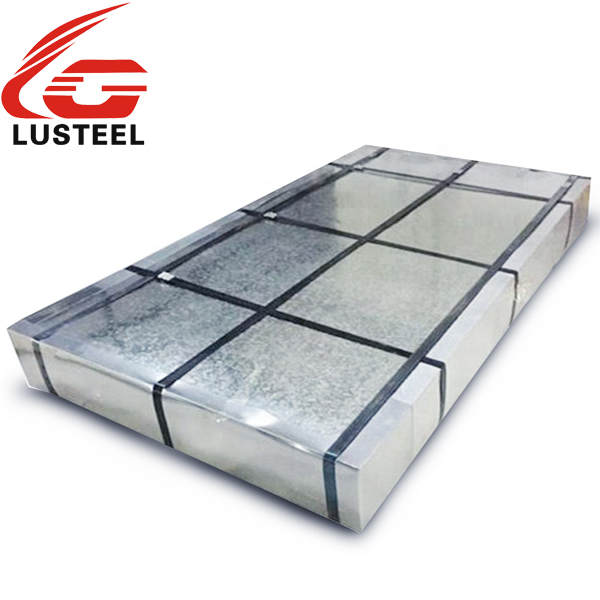

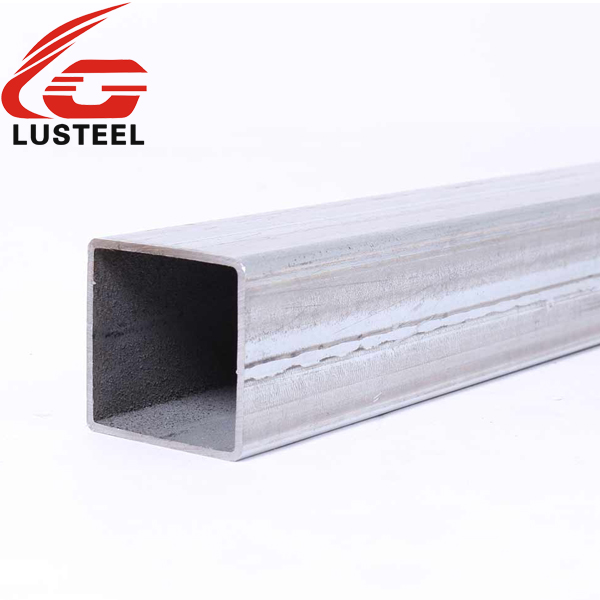

Related Products