Top Tool Steel Manufacturers in China: Quality and Reliability

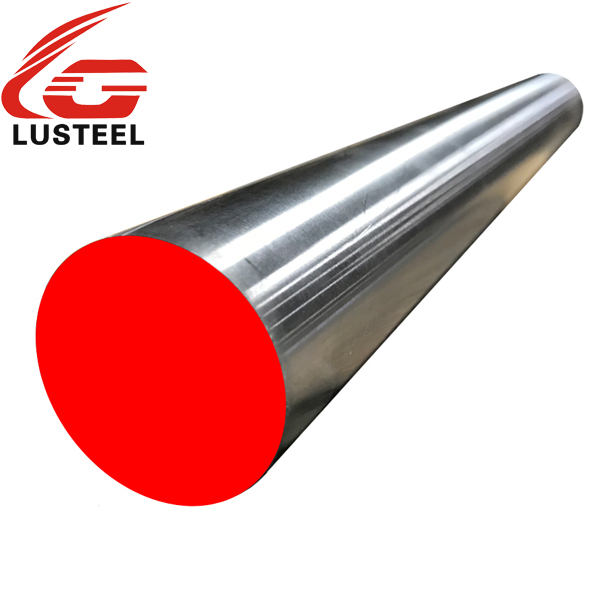

At our company, we specialize in high-quality tool steel, perfect for various industrial applications. Sourced from trusted manufacturers in China, our tool steel meets rigorous standards to ensure durability and performance. Whether you're in need of materials for machining, dies, or molds, we've got you covered. I’ve experienced firsthand how our tool steel enhances productivity and results in long-lasting performance. Our competitive pricing and reliable supply chain make us a go-to choice for B2B purchasers like yourself. With a variety of grades and specifications available, I am confident you will find the right fit for your projects. Quality is our top priority, and working with us means gaining a partner that understands your needs. Let me help you take your operations to the next level with our premium tool steel from China. Reach out today to discuss how we can support your business needs!

Tool Steel Delivers Unmatched Quality Winning in 2025

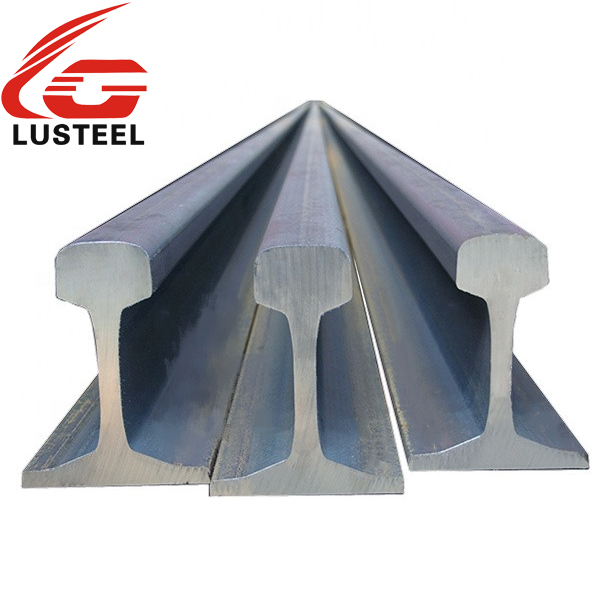

In the competitive world of manufacturing, the choice of materials can make or break a project. Tool steel has emerged as a preferred option for industries seeking resilience, precision, and durability. As we head towards 2025, the advantages of tool steel are more pronounced than ever, providing both performance and cost-effectiveness that attract global purchasers. The inherent properties of tool steel, including high hardness, resistance to abrasion, and exceptional wear resistance, make it ideal for various applications—from cutting tools to molds and dies. The evolution of manufacturing technologies has further enhanced the capabilities of tool steel, with innovations leading to even finer quality and performance. Manufacturers around the globe are now able to maximize productivity while reducing downtime, thanks to the consistent reliability of tool steel products. This trend positions tool steel as not just a material choice, but as a strategic asset that companies can leverage to outperform competitors in an increasingly demanding market. As we look forward to 2025, the commitment to unmatched quality in tool steel production will play a pivotal role in shaping the future of manufacturing. Global purchasers are encouraged to consider the long-term benefits of investing in high-quality tool steel to ensure superior performance and greater return on investment. With an eye on advancing their operational efficiency and product standards, businesses should partner with suppliers who uphold excellence in tool steel manufacturing.

Tool Steel Delivers Unmatched Quality Winning in 2025

| Material Type | Hardness (HRC) | Tensile Strength (MPa) | Applications | Heat Treatment Method |

|---|---|---|---|---|

| D2 Tool Steel | 58-62 | 2000 | Cutting Tools, Dies | Air Quenching |

| O1 Tool Steel | 45-50 | 1500 | Machining, Knives | Oil Quenching |

| A2 Tool Steel | 56-60 | 2200 | Punches, Blanks | Air Quenching |

| S7 Tool Steel | 50-60 | 1600 | Heavy Duty Tools | Air Quenching |

| M2 Tool Steel | 60-65 | 2500 | Drills, End Mills | Air Quenching |

Related Products