Low Alloy Steel Plate Manufacturer in China - Quality & Durability

When it comes to sourcing quality low alloy steel plates, I’ve found that partnering with a reliable China manufacturer is key. These plates are not just durable, but they also offer great strength-to-weight ratios, making them ideal for various applications including construction and engineering. I’ve seen firsthand how these materials hold up under pressure, making them a smart investment for any project. The low alloy composition enhances performance, ensuring resistance to wear and tear, which is crucial for heavy-duty operations. Working with a Chinese manufacturer has its advantages too, including competitive pricing and efficient bulk ordering options. Whether you’re in the automotive or structural sector, having access to such high-quality plates can significantly elevate the quality of your projects. If you're serious about improving your supply chain, let’s connect and explore how these low alloy steel plates can meet your needs and enhance your operations.

Low Alloy Steel Plate Dominates Sets the Industry Standard

In the rapidly evolving landscape of the steel industry, low alloy steel plates have emerged as a predominant choice for various applications, setting new standards for performance, durability, and versatility. These materials combine the best of both worlds—strength and weldability—making them ideal for sectors such as construction, manufacturing, and automotive. As global demands grow for high-quality, resilient steel solutions, low alloy steel plates are proving to be indispensable in meeting these industry needs. What sets low alloy steel plates apart is their unique composition, which includes elements such as manganese, nickel, and chromium. These alloys not only enhance the mechanical properties of the steel but also improve its resistance to wear and fatigue. With advancements in production technology, manufacturers can now offer a range of thicknesses and dimensions, allowing for customized solutions tailored to specific project requirements. This adaptability ensures that businesses around the world can rely on low alloy steel plates to meet rigorous standards and regulations while optimizing their operational efficiencies. As global procurement practices evolve, partners in the steel supply chain are increasingly seeking reliable suppliers who prioritize quality and sustainability. Low alloy steel plates are a sustainable choice, helping reduce waste and energy consumption throughout their lifecycle. By investing in these materials, businesses can not only enhance their product offerings but also demonstrate a commitment to environmentally responsible practices. As the industry continues to advance, embracing low alloy steel plates will position companies at the forefront of innovation and competitiveness in the global market.

Low Alloy Steel Plate Dominates Sets the Industry Standard

| Material Grade | Tensile Strength (MPa) | Yield Strength (MPa) | Thickness (mm) | Width (mm) | Length (mm) |

|---|---|---|---|---|---|

| Q345B | 490 | 355 | 6 | 1500 | 6000 |

| S355J2 | 470 | 355 | 8 | 1200 | 8000 |

| ASTM A572 | 450 | 300 | 10 | 1400 | 7000 |

| EN 10025 | 430 | 280 | 12 | 2000 | 6000 |

| Api 5L X80 | 580 | 420 | 8 | 1500 | 12000 |

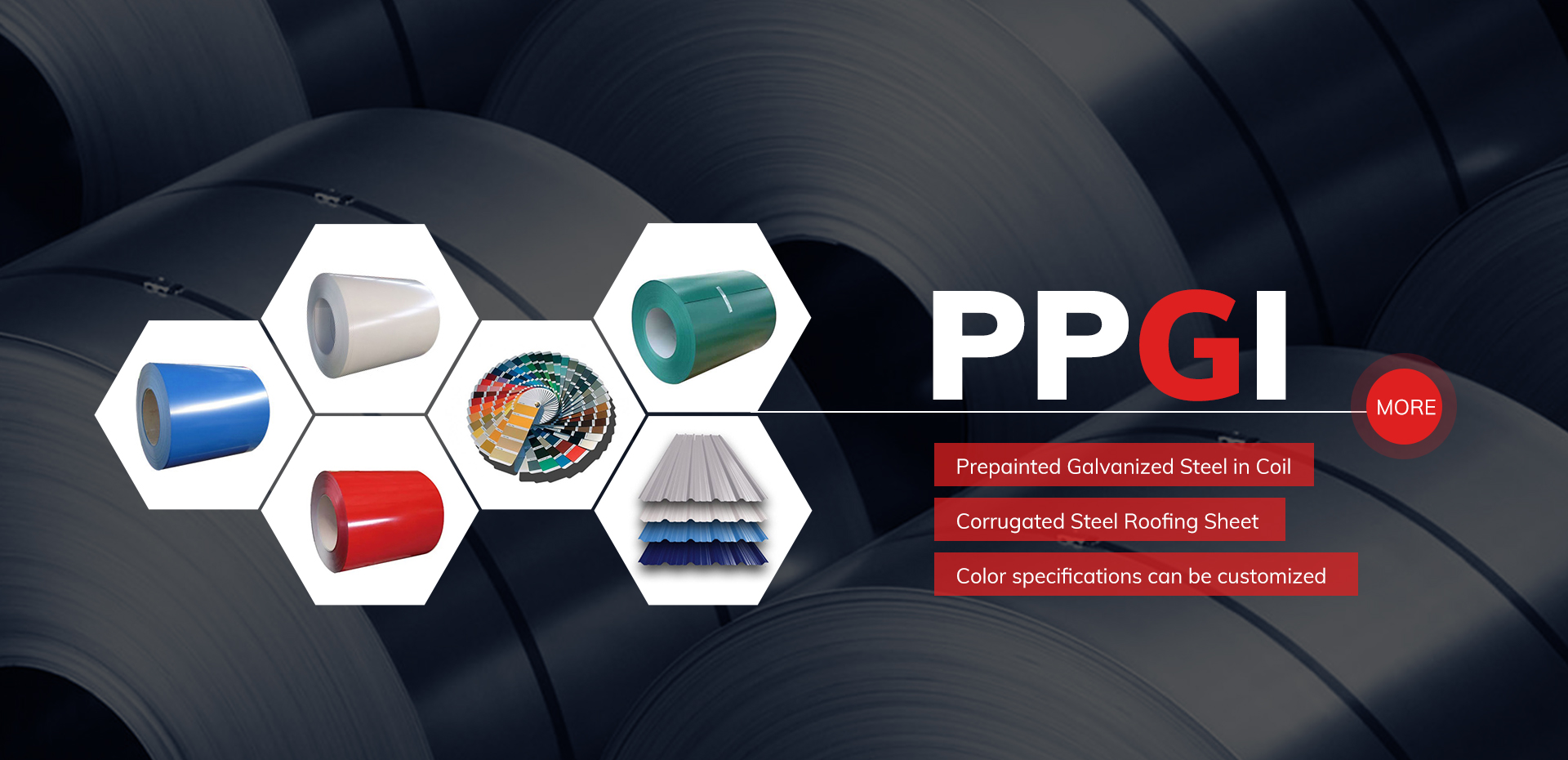

Related Products