Top China Manufacturer of Spirally Welded Steel Pipes for Reliable Solutions

When it comes to robust and reliable piping solutions, I stand by my choice of Spirally Welded Steel Pipes from a reputable manufacturer in China. These pipes are designed to meet a wide range of industrial needs, boasting exceptional strength and durability thanks to their unique spiral welding technique. They’re perfect for applications in construction, oil and gas, and water supply systems. What I appreciate about these pipes is their ability to handle high pressure and harsh environments, making them a solid choice for any project. Plus, sourcing from a trusted manufacturer in China ensures not only competitive pricing but also quality assurance. I’ve found that flexibility in sizes and specifications allows for custom solutions tailored to specific requirements. Ready to elevating your project with top-tier Spirally Welded Steel Pipes? Partnering with the right supplier can make all the difference, and I can vouch for the reliability and performance of these products.

Spirally Welded Steel Pipes Manufacturer For the Current Year

In the current landscape of global manufacturing, the demand for high-quality spirally welded steel pipes remains robust, driven by infrastructure developments and energy projects worldwide. These pipes, known for their durability and efficient production process, are increasingly favored in various applications, including oil and gas, water supply, and construction. As industries evolve and expand, sourcing reliable suppliers is paramount. Companies looking to procure spirally welded steel pipes should prioritize manufacturers that utilize advanced technology and adhere to international quality standards. This ensures that the products not only meet rigorous performance criteria but also deliver long-term reliability and safety in challenging environments. Working with leading manufacturers can also provide flexibility in customization to meet specific project requirements, enhancing operational efficiency and reducing installation times. As we progress through this year, manufacturers that align sustainability practices with their production processes are becoming increasingly important. Eco-friendly production methods and quality certifications will likely influence procurement decisions, allowing businesses to meet their environmental goals while securing top-tier materials. Choosing the right supplier can empower companies to thrive in a competitive global market, ensuring they have the best resources for upcoming projects.

Spirally Welded Steel Pipes Manufacturer For the Current Year

| Product Type | Diameter (mm) | Thickness (mm) | Length (m) | Material Grade | Certification |

|---|---|---|---|---|---|

| Spiral Welded Pipe | 219 | 6 | 12 | X42 | API 5L |

| Spiral Welded Pipe | 273 | 8 | 10 | X46 | ISO 3183 |

| Spiral Welded Pipe | 325 | 10 | 6 | X52 | ASTM A252 |

| Spiral Welded Pipe | 406 | 12 | 8 | X56 | API 5L |

| Spiral Welded Pipe | 508 | 15 | 5 | X60 | ISO 3183 |

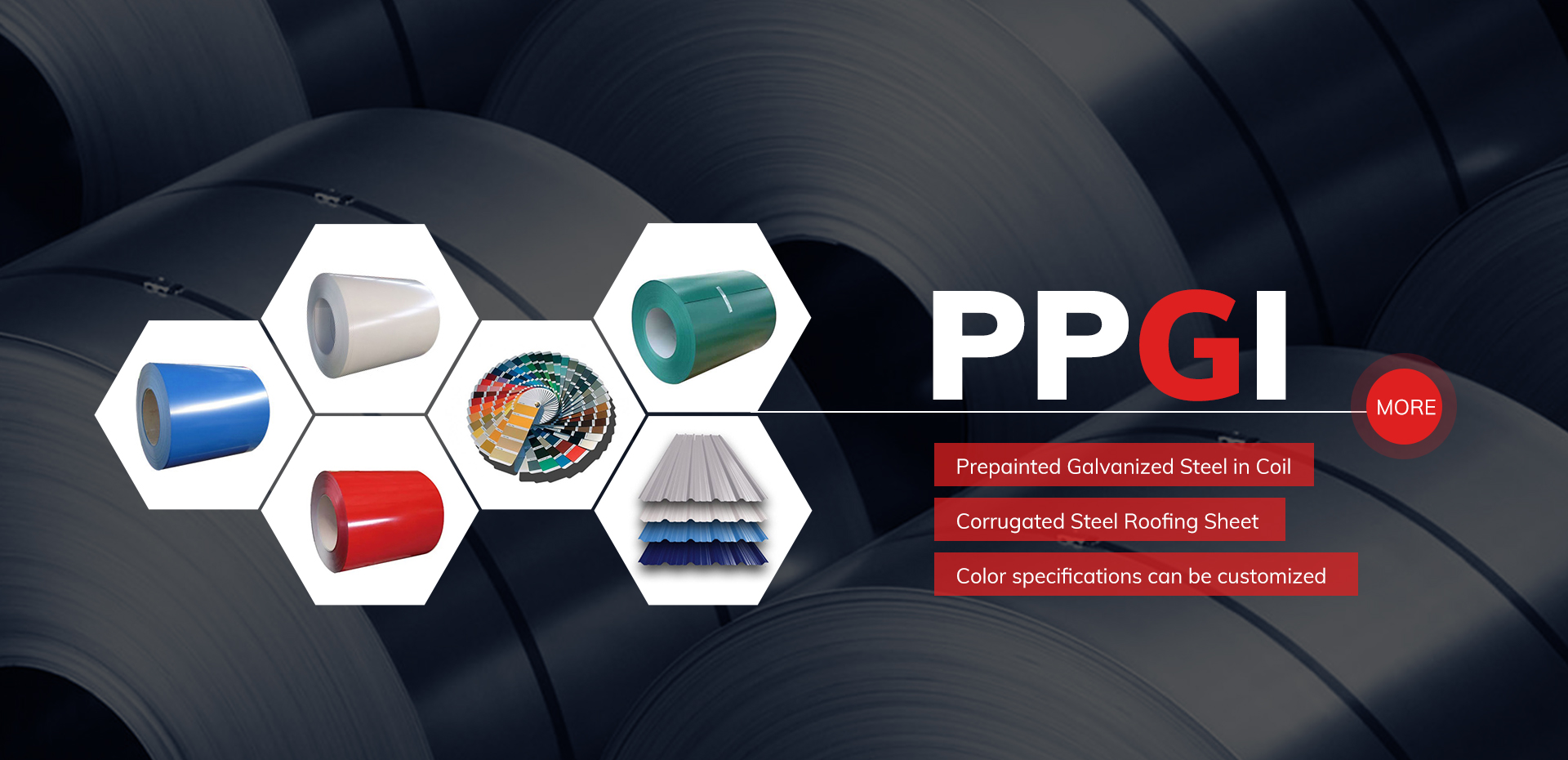

Related Products