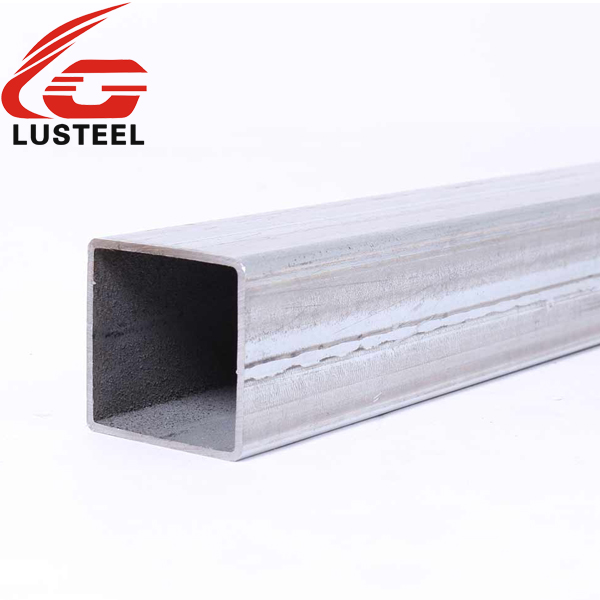

Top China Manufacturer of Galvanized U Sections for Quality Construction

When it comes to reliable and durable structural components, I often recommend galvanized U sections. These versatile products are essential for a range of construction and engineering applications. Sourced directly from reputable manufacturers in China, our galvanized U sections boast superior corrosion resistance, ensuring long-lasting performance even in challenging environments. I find that these sections not only provide excellent strength but also offer flexibility for various designs. Whether you’re working on large-scale construction projects or smaller renovations, our galvanized U sections can meet your needs. The precision manufacturing from trusted Chinese suppliers guarantees consistent quality and dimensions, making my sourcing decisions easier. Choosing the right galvanized U sections can make a significant difference in project efficiency and durability. With our products, you’ll gain the reliability and performance necessary to complete your projects on time and within budget. Let’s elevate the quality of your builds with top-notch galvanized U sections today!

Galvanized U Sections Products Supplies the World\u2019s Top Brands

In the rapidly evolving world of construction and manufacturing, the demand for high-quality galvanized U sections has never been more pronounced. These products play a crucial role in a variety of applications, from structural support to aesthetic enhancements, and their versatility makes them a staple for many industries. As global procurement managers seek reliable suppliers, understanding the benefits and features of galvanized U sections becomes paramount. Galvanized U sections offer exceptional durability and corrosion resistance, making them ideal for use in harsh environments. The galvanization process provides a protective barrier that extends the lifespan of the steel, ensuring that it can withstand weathering, moisture, and other challenging conditions. This longevity not only reduces maintenance costs but also enhances the overall efficiency of projects. Buyers interested in quality and reliability will find that premium U sections can meet rigorous standards and specifications, aligning with the needs of various applications, including construction, transportation, and infrastructure development. Furthermore, sourcing galvanized U sections from established manufacturers ensures consistency and quality control throughout the production process. With a wide range of sizes and specifications available, procurement managers can easily find products tailored to their specific requirements. Establishing partnerships with trusted suppliers also facilitates streamlined logistics and helps maintain project timelines, allowing businesses to focus on their core competencies. By prioritizing high-quality galvanized U sections, companies can enhance their competitive edge and support sustainable growth in an increasingly demanding marketplace.

Galvanized U Sections Products Supplies the World’s Top Brands

| Product Type | Material Grade | Dimension (mm) | Surface Treatment | Usage |

|---|---|---|---|---|

| U Section | S235JR | 100 x 50 x 4 | Galvanized | Construction |

| U Section | S275JR | 150 x 75 x 5 | Galvanized | Structural |

| U Section | S355JR | 200 x 100 x 6 | Hot Dip Galvanized | Support Structures |

| U Section | S235JR | 80 x 40 x 3 | Electro Galvanized | Manufacturing |

| U Section | S275JR | 120 x 60 x 5 | Galvanized | Transport |

Related Products